Enjoy a seamless overview of ground conditions early in the project, thereby reducing cost and saving time.

Our specialized service provides the missing link between complex geophysical and sparse geotechnical data. By combining our extensive project experience with efficient and accurate machine learning routines, we provide full 3D coverage with quantified precision.

A geoscanning survey penetrates hundreds of meters below the surface.

Combined with geotechnical drillings strategically located based on the survey - we identify risks such as:

Infrastructure development usually involves changes to local slopes. Excavation or backfilling works affect slope stability. A sound geotechnical understanding is necessary to ensure safe ground conditions during and after construction.

Infrastructure construction typically involves excavation and rearrangement of large volumes of material. Whether that is soft soil or solid rock is the cost-determining factor in many projects.

Infrastructure construction typically involves excavation and rearrangement of large volumes of material. The type of rock can be the cost-determining factor in some projects.

Rock quality has a major influence on, for example, tunnel excavation and rock support methods, both during and after construction. These factors typically govern the feasibility of a project.

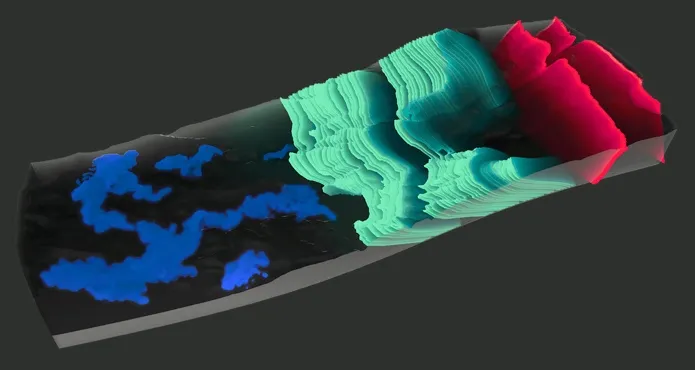

Finally, our team of experts combine all the data using machine-learning algorithms.

Creating full coverage 3D models that let us detect and assess key geophysical factors.

Our technology and method are proven in large scale projects since 2009. We mapped all planned rail infrastructure in Norway for the coming 16 years, all in one summer. We examined 90 km of road in 5 days. Our customers save time and money - Nye Veier saved 24 mill USD, reducing drilling by 30%.

All we need to know is where your project is located, its size and particular geological unknowns. Based on that we can assess technological feasibility and economic benefit.

Once we thoroughly assessed the added value of our method for your goals and received an order, you lean back and we care for data acquisitions, harvesting, integration and machine-learning based model building.

Working with EMerald you won’t need domain specialists to make sense of the sensed. We deliver and give easy access to integrated 3D models that provide the insights your project needs.